Innovative and fit-for-purpose design was the winning formula that secured WEG Automation Africa, formerly Shaw Controls, the contract for a containerised substation and control room solution for a remote tin mine in the Democratic Republic of Congo.

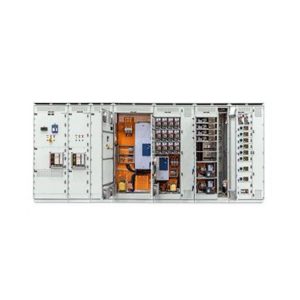

According to Tyrone Willemse, business development consultant – projects and contracts at WEG Automation Africa, the isolated location of the mine and the challenging logistics made the modular solution ideal for the mine. The substations are each housed in a six-metre-high cube container. A total of 14 units were supplied, comprising MV rooms and LV rooms.

Willemse says. “The unit’s dimensions and robustness had to allow for a long journey, including along a very difficult 200 km road to reach the mine site.”

“Every part of the process plant has its own designated MCC that provides electrical power and control for areas including the primary crushing circuit, the plant feed, regrind mill, tailings thickener, and the product dewatering and handling circuits.”

In addition to meeting safety compliance regulations, the design includes three-way locking systems, LED lighting, fire detection systems and a safety interlock to the fire system for air conditioners. Backup power supply is provided to all the exit lighting. To ensure easy cable entry, glanding plates were carefully located not to overlap with the container’s support beams.

“Working in close collaboration with the engineering house, careful planning could be done upfront to ensure that nothing was overlooked,” Willemse says.

“In the design, full consideration was given to the placement of elements like platforms, walkways, doors, viewing windows and air conditioning units,” he says. “We also took responsibility for the logistics of getting everything to site.”

Willemse highlights that this turnkey solution demonstrated WEG Automation Africa’s containerised substation design and engineering capability, as well as its full local manufacturing capacity lifting it above other MCC manufacturers or assemblers. The containerised solution comes with a full data pack, quality control documentation and an operation and maintenance manual in accordance with ISO9001.

“With our expertise, capacity and experience of working in Africa, we were able to reduce the risk and turnaround time by tackling the entire contract in-house,” Willemse says. “The extensive testing and cold commissioning enabled by our modus operandi and facilities also gave the mine peace of mind that the unit would function as required when it arrived on site.”