Custom built E-Houses offer a rapid and far more cost effective alternative to the building of brick and mortar substations, and this is especially true in an underground application. This is one of the reasons why Zibulo Colliery contracted Shaw Controls, a division of Zest WEG Manufacturing, to design and manufacture an E-House for its operation in the Mpumalanga coalfields.

Containerised electrical control installations in underground applications are not new. Bevan Richards, COO of Shaw Controls, says the concept was first used during the sinking of many of South Africa’s gold mining vertical shafts when ISO marine containers were equipped with mimic panels and other ancillary equipment.

“However, the evolution and development of pre-manufactured electrical substations or E-Houses has opened up numerous possibilities including the ability to completely customise the unit according to process and plant requirements,” Richards explains.

Specifically designed for this underground application in a coal mine, the E-House was designed with several specific parameters taking precedence. Underground height restrictions meant that the structure itself had to be lower than usual but would still need to accommodate all necessary electrical infrastructure and allow for sufficient headroom for cooling.

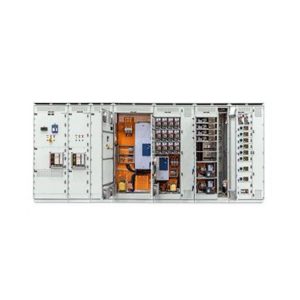

Richards says it is testimony to Shaw Controls’ mechanical design capability that its engineers were able to design such a low profile steel structure that could house all the equipment and still maintain the requisite internal clearances. He says that extensive use was made of Solid Works CAD software during the design process and this ensured the integrity of the design. The final E-House dimensions are a height of 2.3 metres, a length of 8.5 metres and a 3.5 metre width.

Another important criteria that had to be met was the voltage being used on the mine. Majority of mines use 525 Volts, but in the instance of Zibulo Colliery the voltage being used is 1 000 Volts. This required special design work on both the Motor Control Centre (MCC) and the Variable Speed Drive(VSD) to ensure safe operation at 1 000 Volts.

Operation in a coal mining application brings with it additional specifications and these were met by equipping the E-House with a fire detection and suppression system.

The E-House is the prime power centre for an underground trunk belt conveyor which is driven by three 400 kW WEG 1000 Volt motors. The conveyor belt with a width of 1.8 metres belt speed of 4.9 metres per second has been designed to transport 4 800 tph.

The complete E-House including the base, cladding (side walls and roof) and all internal electrical equipment was designed and manufactured by Shaw Controls at its modern comprehensively equipped facility in Johannesburg. The system was integrated internally at the factory and the complete solution, load tested in the factory environment to prove its functionality prior to installation underground.

Richards says that to facilitate the load testing requirement of such a large kW power load a third party test facility was used and Shaw Controls was responsible for the co-ordination of the connection of an 11 kV power centre, the E-House and the water cooling skid and VSDs at the test centre.

Commenting on the differentiators that Shaw Controls is able to offer the market, Richards says that the company is primarily an electrical engineering company and therefore does not have to rely on a third party electrical manufacturing company to produce the MCC or to integrate it into the E-House substation.

“This is a major advantage as we are a single supply source that has the resident electrical and mechanical skills, and we have a solid reference base of successfully operating E-Houses,” Richards concludes.